Sheet metal bending in action. Complicated Gutter made easy!

Bending 5/16″ thick steel plate in a press brake.

Metal Bending Capacity

“What can you bend?”

We measure bending capacity by several factors. These include tonnage, material type, bottom vee die tooling width, and obviously part profile. You cannot physically bend the metal if you don’t have enough tonnage, and you cannot achieve a bend without the correct tooling. Please always inquire about specific parts, but as a general rule you can follow this guide.

| Thickness or Gauge | Maximum Bend Length | Bend Length Limiting Factor | Minimum Flange OD size | Inside Bend Radius (approx.) |

How we cut the material |

|---|---|---|---|---|---|

| Over 1/2" | No Bending | Tooling | Varies | Varies | Laser or Saw |

| 1/2" | 6'-4" (76") | Tonnage | 2.875" | 0.625" | Laser or Saw |

| 3/8" | 8'-6" (102") | Tonnage | 2.125" | 0.469" | Laser or Saw |

| 5/16" | 10'-0" (120") | Tooling Length Max 120" | 1.875" | 0.391" | Laser or Saw |

| 1/4" | 12'-0" (144") | Tooling Length max 144" | 1.4375" | 0.3125" | Shear, Laser, Saw |

| 3/16" | 14'-0" (168") | Shear Capacity, Brake Length | 1.0625" | 0.234" | Shear, Laser, Saw |

| 10 (0.1345") | 14'-0" (168") | Shear Capacity, Brake Length | 0.8125" | 0.195" | Shear, Laser (up to 156") |

| 12 (0.1345") | 12'-0" (144") | Tooling Length max 144" | 0.625" | 0.156" | Shear, Laser |

| 14 (0.747") | 14'-0" (168") | Shear Capacity, Brake Length | 0.5" | 0.098" | Shear Laser (up to 156") |

| 16 (0.598") 18 (0.487") |

It's complicated | Variety of factors | 0.375" (<= 144") 0.5" (> 144") | 0.083" | It's complicated |

| 20 (0.478") & Thinner |

It's complicated | It's complicated | It's complicated | It's complicated | It's complicated |

Metal Bending Machine List – Description

- RAS XXL Folding Brake – Electric – 21′-0″ length. CNC Controlled with bending simulation. 16 gauge capacity with minimum 1/2″ flange lengths. Ideal to leave flange on one end at least 3/4″. Minimum 48″ part length.

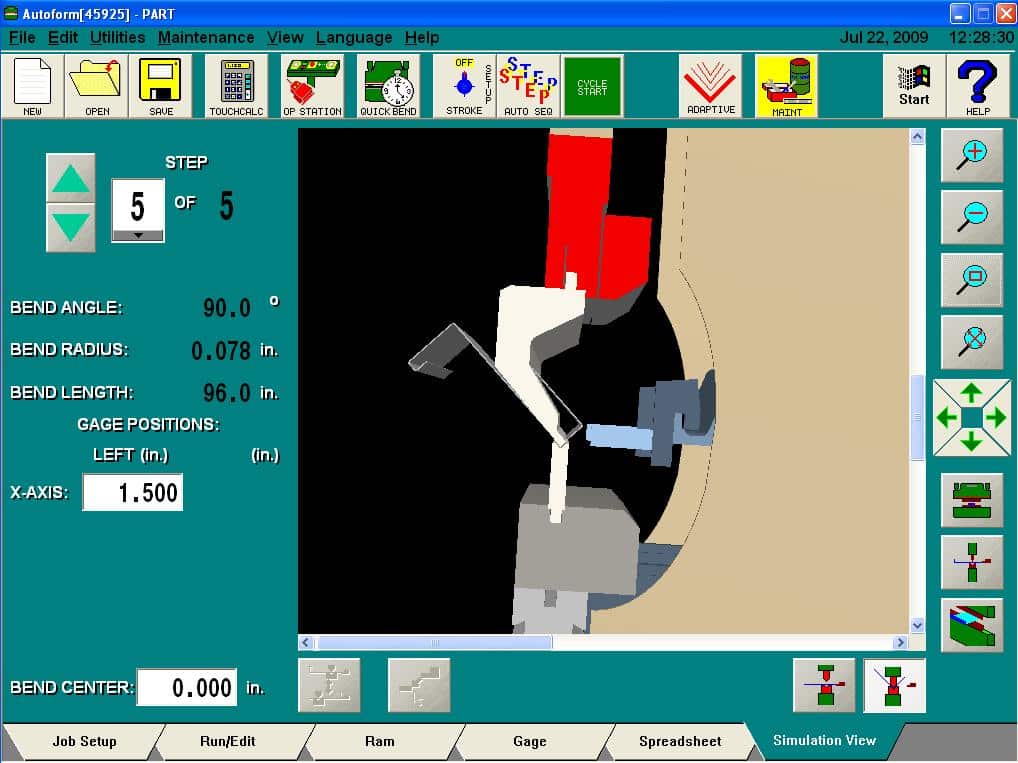

- Cincinnati – 230 Ton Hydraulic – 14′ bed, 12′-6″ between frame. CNC Controlled with user PC touch screen interface & bend simulation. Auto Crown ensures consistent bends throughout part.

- Cincinnati – 135 Ton Hydraulic – 12′ bed, 10′-6″ between frame. Frame is built with extra deep opening to allow more capability with 12′ parts. This brake has 14″ stroke length to handle extra tall tooling. CNC Controlled with user PC touch screen interface & bend simulation. Auto Crown ensures consistent bends throughout part.

- Cincinnati – 90 Ton Hydraulic – 10′ bed, 8′-6″ between frame. CNC Controlled with user PC touch screen interface & bend simulation. Auto Crown ensures consistent bends throughout part.

- Accurpress- 175 Ton Hydraulic 12′ Hemming Die – 20 ga. capacity – We use this machine to form 1/2″ open and closed hems only. Minimum Hem is 3/8″ in 24 gauge Steel or Stainless Steel, & .040″ Aluminum

- Chicago Hand Brake – 10′ leaf brake.

- 4′ Hand box & pan brake

Metal Bending Equipment Gallery:

Click images of the forming equipment we use for an enlarged image and detailed description of the capacities.