Architectural Spandrel Panels – Liberty Media Headquarters

These architectural spandrel panels, originally designed cut from solid aluminum plate, pose a large problem from a fabrication standpoint. The initial 36-week lead time to the General Contractor wasn’t an acceptable option either. With cost and schedule in mind, H&H, along with the architect, found a better solution.

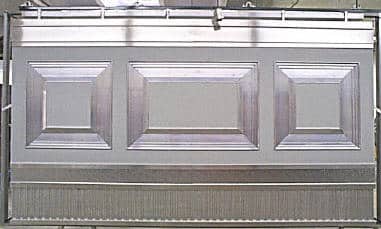

Aluminum angle and I-beam sections make up the skeleton of these architectural spandrel panels, with 6mm Reynobond® ACM adhered to the face. H&H came up with two special extrusions to form the 6 panel door look and the vertical fluted base. The reveals consist of .040″ aluminum with a sheet of specular “honeycomb” material in between. Brake metal trim finishes out the top and bottom of the panels.

Shop prefabricated, these panels are put in place by crane at the job site. Due to the panels being completely built in our shop, installation requires minimal time. Also, we reduce impact on and already crowded job site . To precisely locate the panels level and square inside stone openings, H&H came up with a specialized mounting jig. This jig concept saves time on layout and makes the panels install with consistency and speed. The architectural spandrel panels follow a design so that no fasteners are visible once the panels are in place. This design makes for a clean panel, that appears to be made from a solid aluminum plate. Just as the architect initially intended.

The result

14 architectural spandrel panels in total, eight weeks fabrication, 5 days to install (mostly window flashings). The result: a spectacular look that not only came in under budget, but on schedule.

Note that these spandrel panels are much more elaborate than our insulated composite spandrel panels we also carry for 1″ and 1/4″ glazing systems. Visit our spandrel panel page for more information relating to that product line.